As the industry carries on to evolve, collaboration in between engineering suppliers, regulatory bodies, and pharmaceutical suppliers might be vital to addressing worries and seizing options in cleanroom sterilization.

Elements that need Specific circumstances, like vacant capsule shells and hygroscopic powders, are saved in a region that is definitely designed to maintain temperature and relative humidity requirements.

The next are definitions of a lot of the units at the moment in position to decrease the contamination rate in aseptic processing:

Monitoring of full particulate depend in managed environments, Despite the usage of electronic instrumentation over a constant foundation, doesn't deliver information on the microbiological content of the natural environment. The basic limitation of particulate counters is they evaluate particles of 0.five µm or more substantial. Although airborne microorganisms are usually not totally free-floating or one cells, they frequently associate with particles of 10 to twenty µm.

Reputable storage alternatives are significant for your fast evolving discipline of biopharmaceuticals. While freezer farms would be the standard in many industries, stroll-in chilly Areas can provide distinct Gains for biopharma firms. Here We'll evaluate The crucial element concerns for deciding on a walk-in chilly storage setting.

Training of all personnel Doing work in managed environments is significant. This education is equally vital for staff answerable for the microbial monitoring system, where contamination of your clean Operating place could inadvertently happen for the duration of microbial sampling.

Microbial Contaminants: Microorganisms, fungi, and various microbes that might cause bacterial infections or spoil drugs. They are particularly concerning for sterile solutions like injectables.

two. The realm needs to be built in this kind of way which the particles should not be generated and will be clean effortlessly. Generally the material like steel id useful for walls and ceiling when the ground must be of Vinyl of Epoxy.

Inform Levels —Microbial amounts, specified in the conventional running procedures, which when exceeded need to bring about an investigation to make website certain the procedure continues to be in Regulate. Inform stages are particular for any provided facility and therefore are proven on The idea of a baseline produced below an environmental monitoring plan.

Automation in cleanroom sterilization is not really pretty much replacing human tasks; It is about producing smart techniques which will adapt to switching disorders and supply constant approach optimization.

Laboratory locations may call for additional stringent controls than unclassified spaces. A laboratory could be a location where investigation, tests, and experiments are performed utilizing possibly dangerous elements. Some samples of laboratories are

The 1987 FDA Guideline on Sterile Drug Products Made by Aseptic Processing suggests that media-fill runs be completed to go over all generation shifts for line/merchandise/container combinations. This guideline need to be regarded not just for qualification media-fill operates, but additionally for periodic reevaluation or revalidation.

The 4000 series Command rate chamber is compatible with just about any dimension bag, bottle or other storage containers. Contact us for the ideal freeze/thaw orientation for your application.

A more info controlled natural environment such as a clean zone or clean room is defined by certification As outlined by a relevant clean room operational normal. Parameters which have been evaluated include filter integrity, air velocity, air patterns, air alterations, and force differentials. These parameters can affect the microbiological bioburden from the clean room operation. The design, building, and Procedure of clean rooms varies tremendously, rendering it hard to generalize requirements for these parameters.

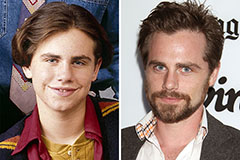

Rider Strong Then & Now!

Rider Strong Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now!